Anaplan hat Syrup Tech akquiriert

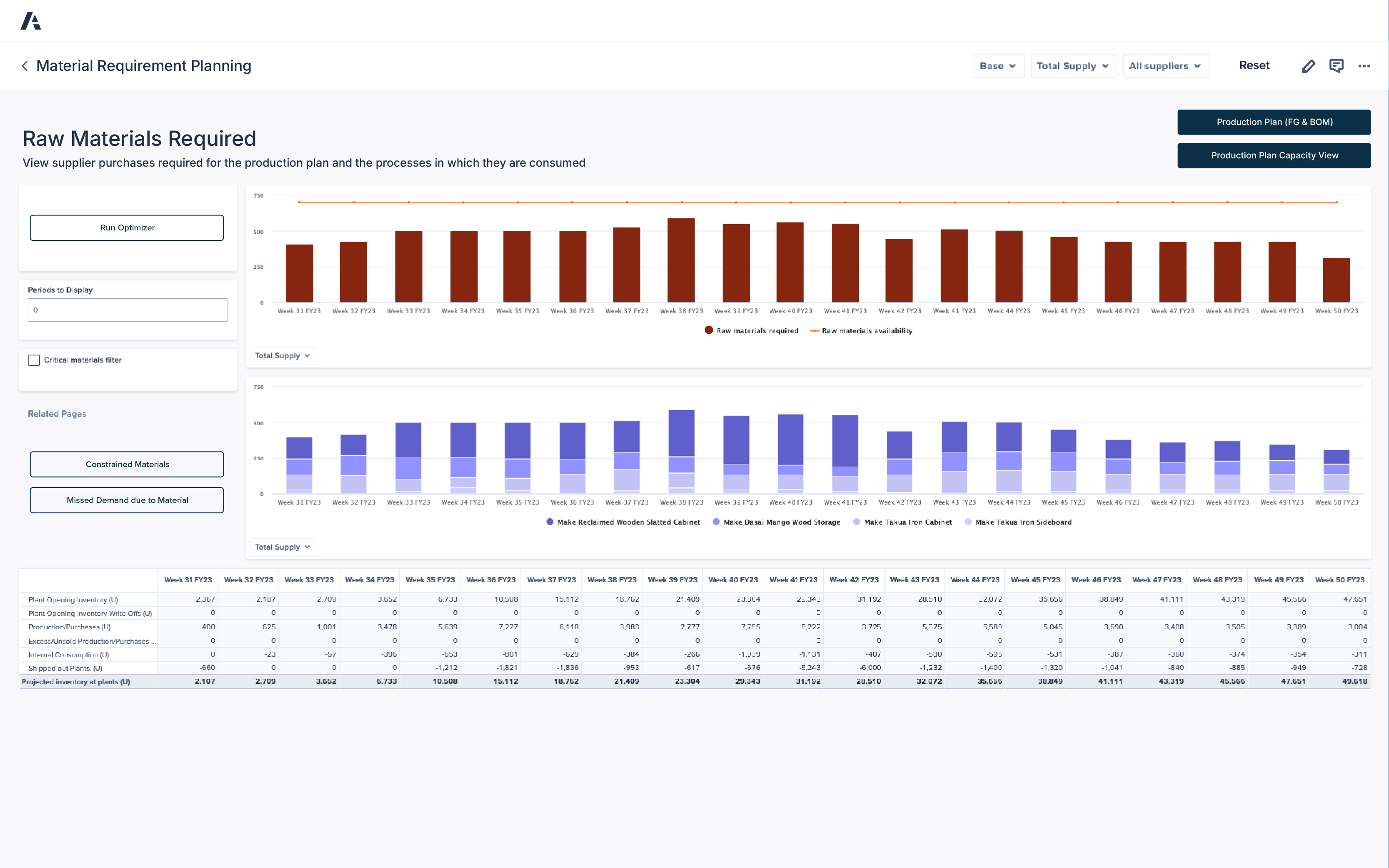

Materialbedarfsplanung (MRP, Material Requirements Planning)

KI-gestützte Lösungen für die Materialbedarfsplanung

Richten Sie Planung, Bestandsmanagement und Beschaffung auf eine intelligentere Produktion aus.

Stellen Sie die richtigen Materialien zur richtigen Zeit bereit

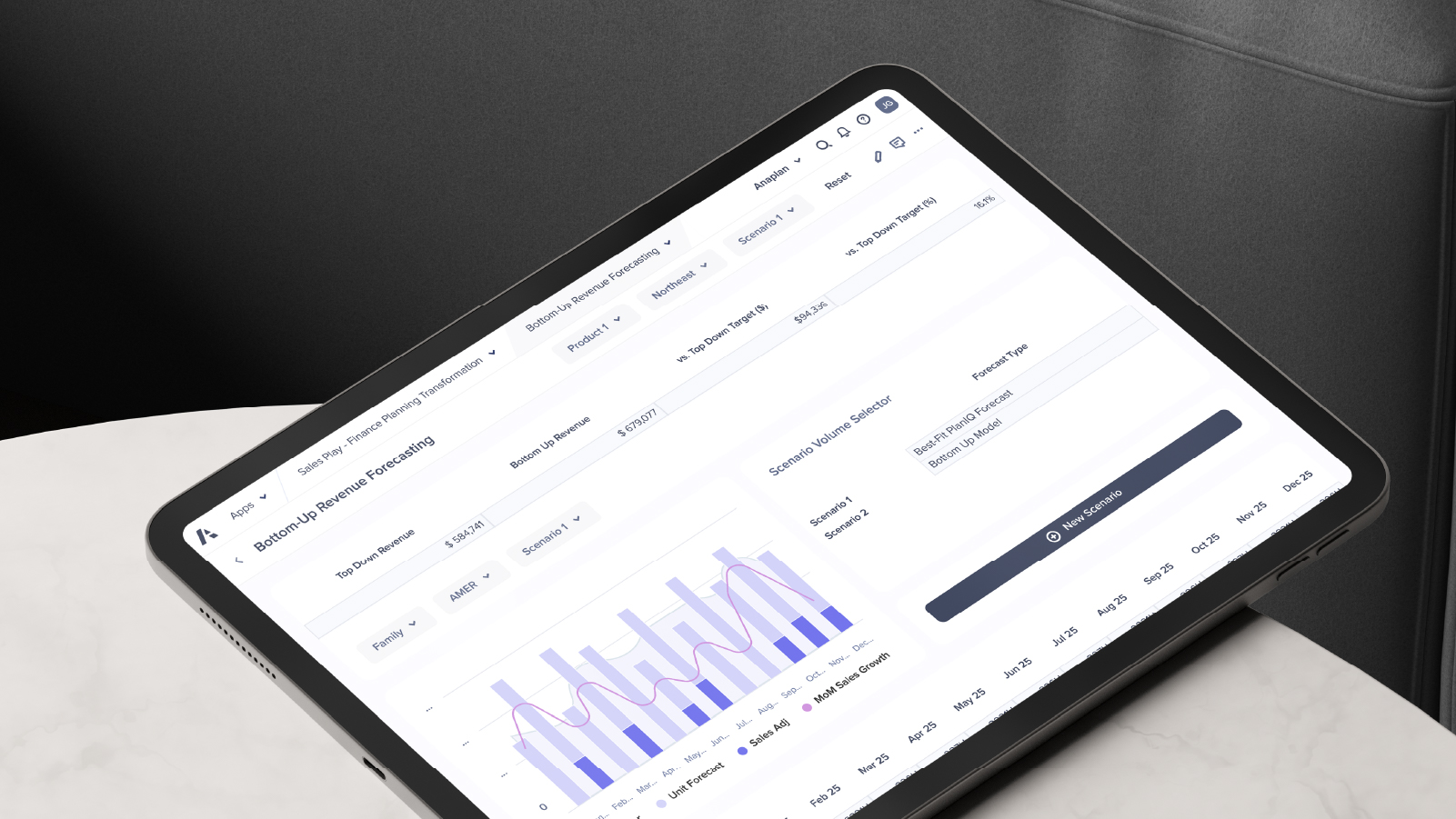

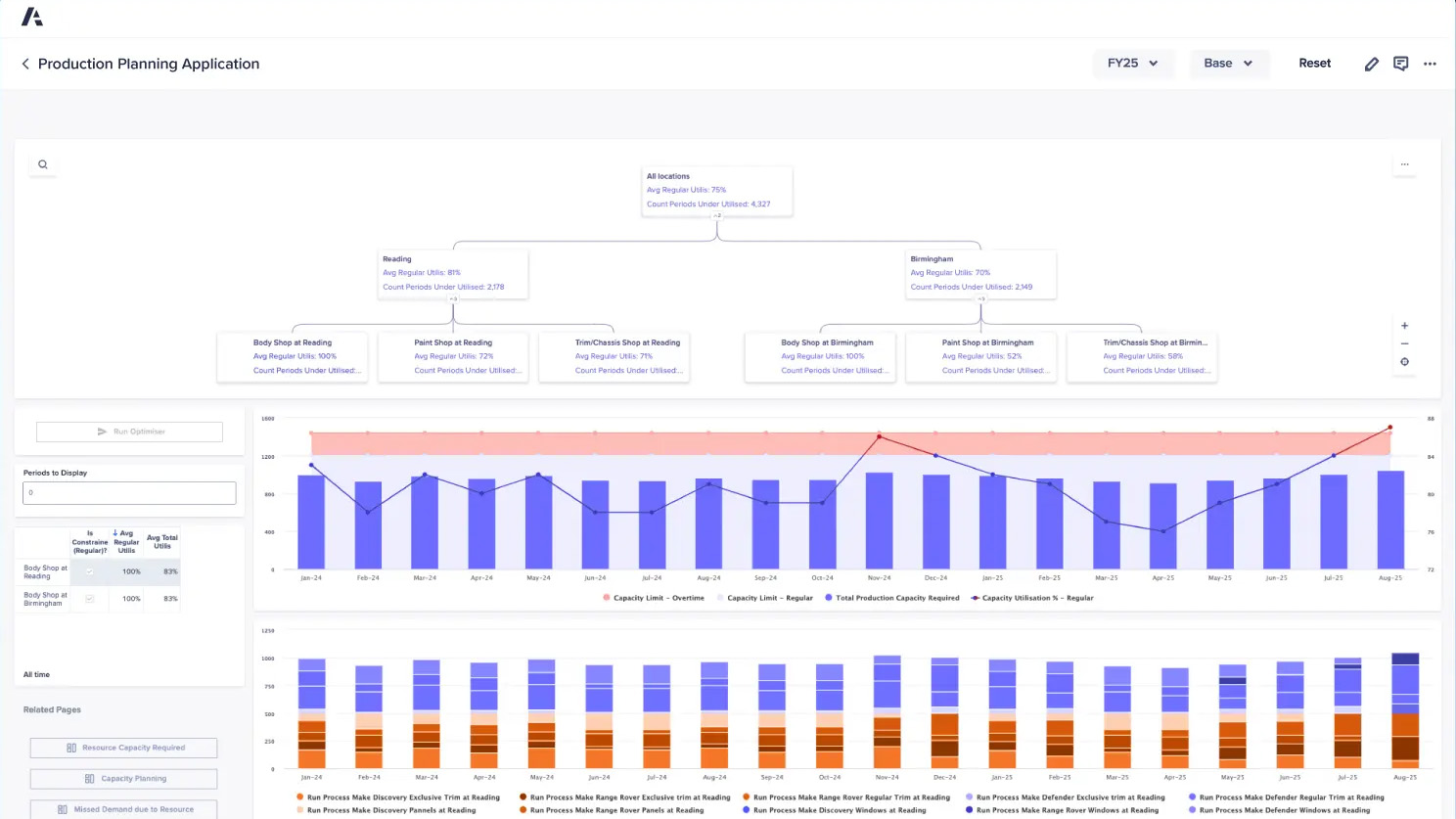

Anaplan Applikation für die Angebotsplanung

Vernetzen Sie Ihre gesamte Supply Chain mit einer speziell entwickelten Applikation, um die Produktions- und Kapazitätsplanung zu optimieren.

Minimieren Sie Risiken und Verschwendung mit

intelligentem MRP

„Mit Anaplan ist uns ein Setup mit wirklich beeindruckendem Funktionsumfang gelungen.“

Kristoffer Halle, SIOP Architect

Entdecken Sie die Plattform, der führende Supply-Chain-Experten vertrauen. Worauf warten Sie?

Supply-Chain-Teams auf der ganzen Welt vertrauen auf Anaplan, um ihr Unternehmen zu modernisieren und zu vernetzen. Wie steht es mit Ihnen?