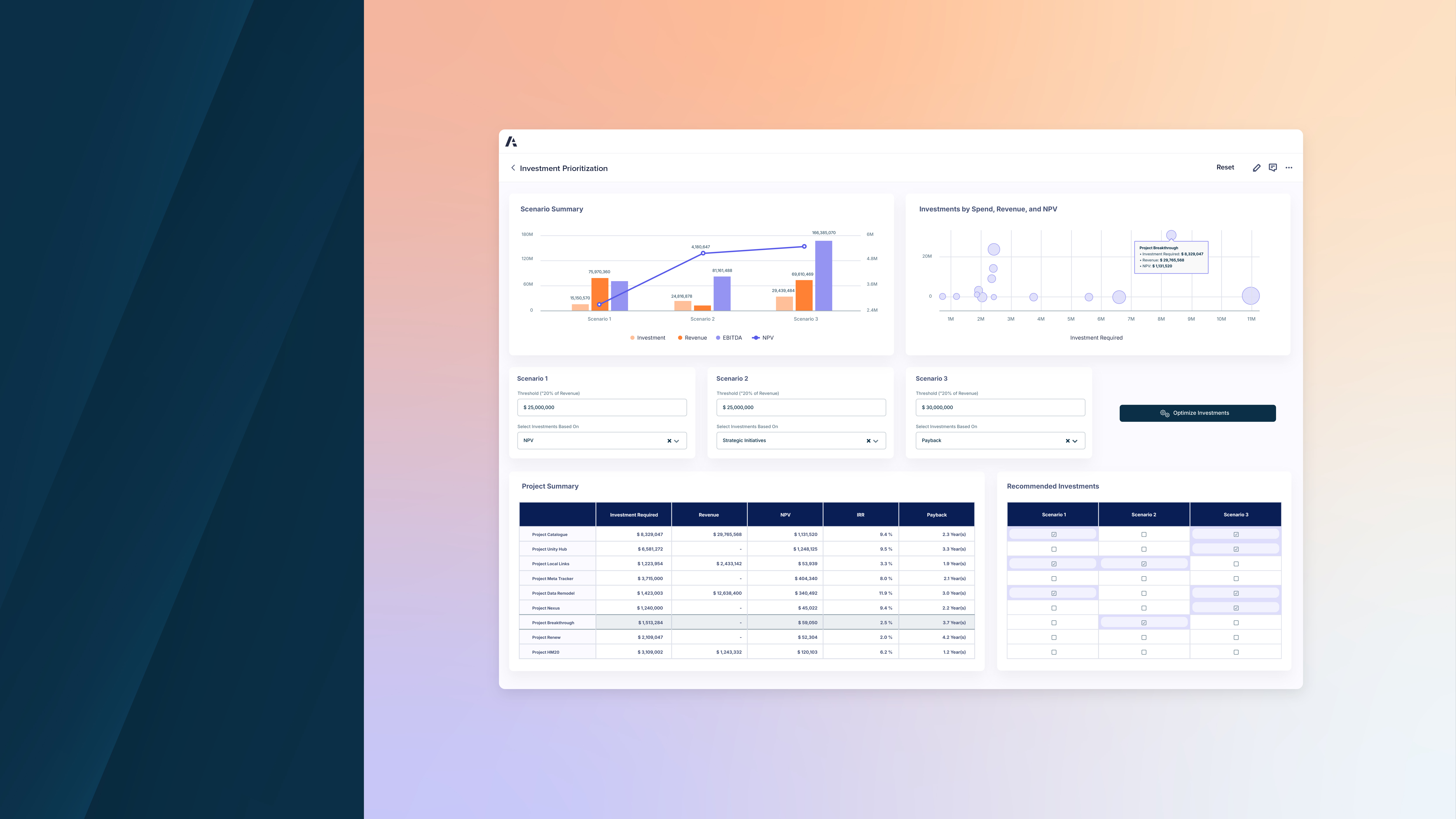

Anaplan named Exemplary Leader in 2025 ISG Buyers Guide™ for Supply Chain Planning: Software Provider and Product Assessment

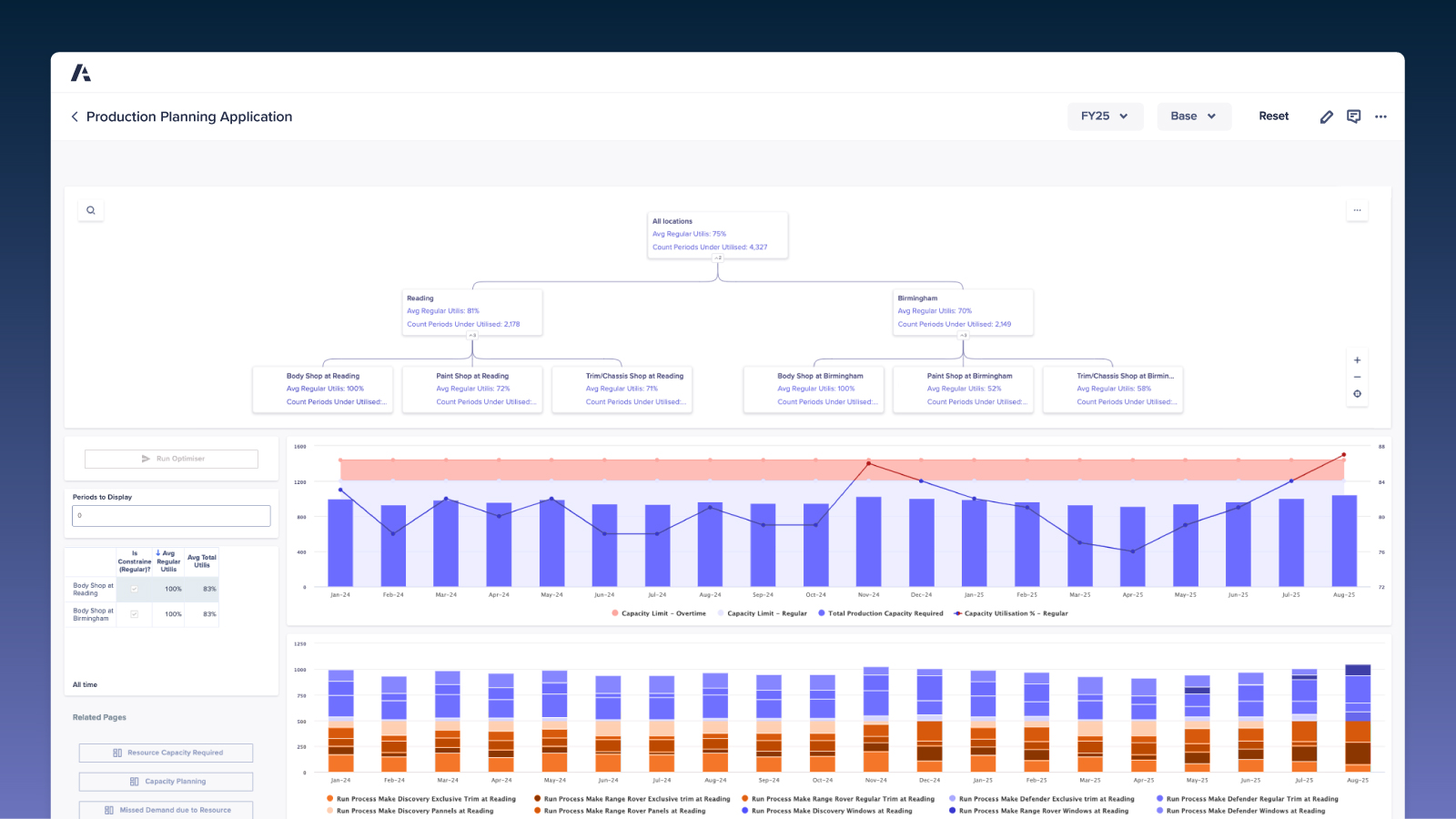

Determine required capacity while considering factors like routing and process times, planning data, shift patterns, overtime, and contracted capacity.