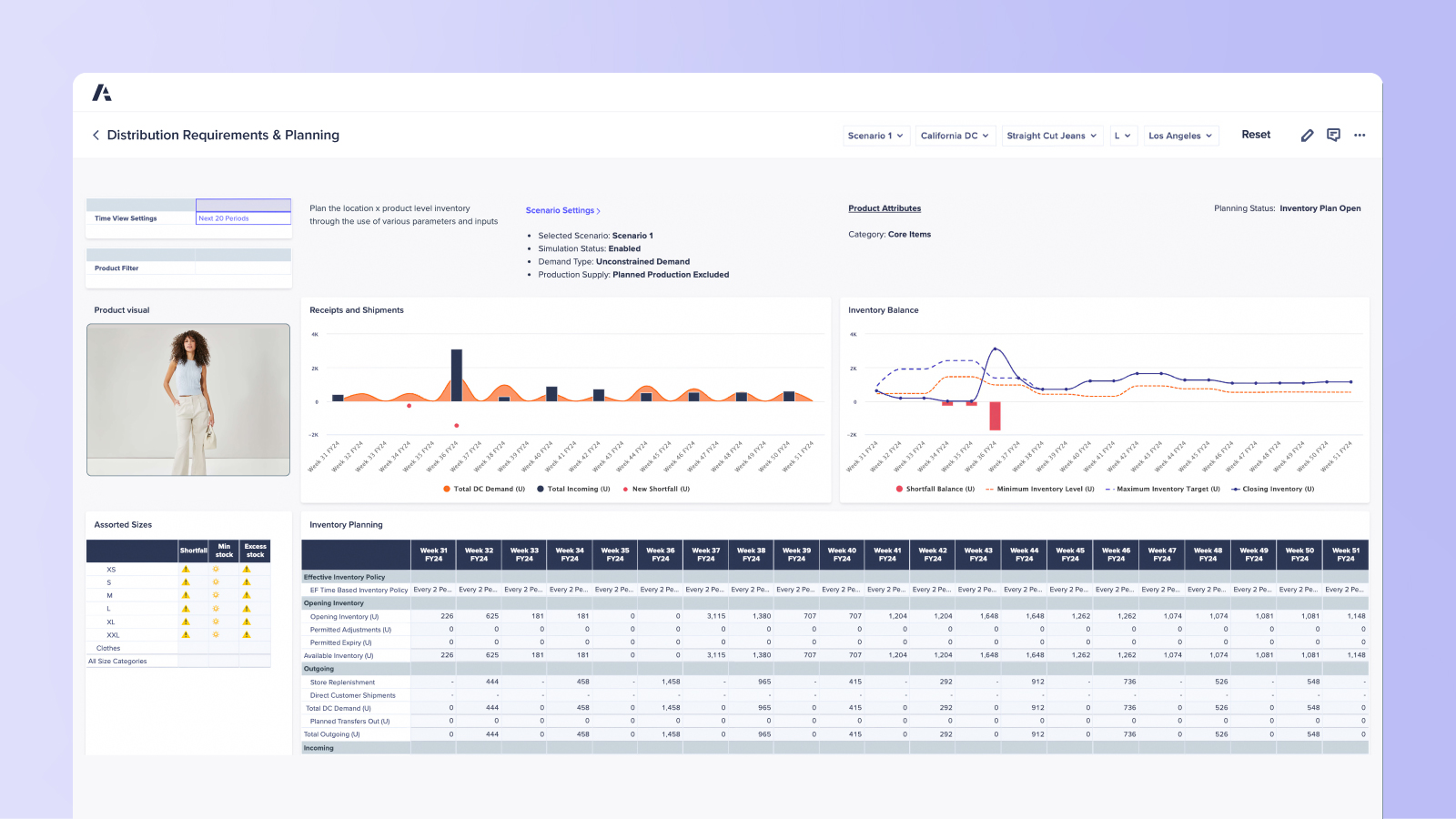

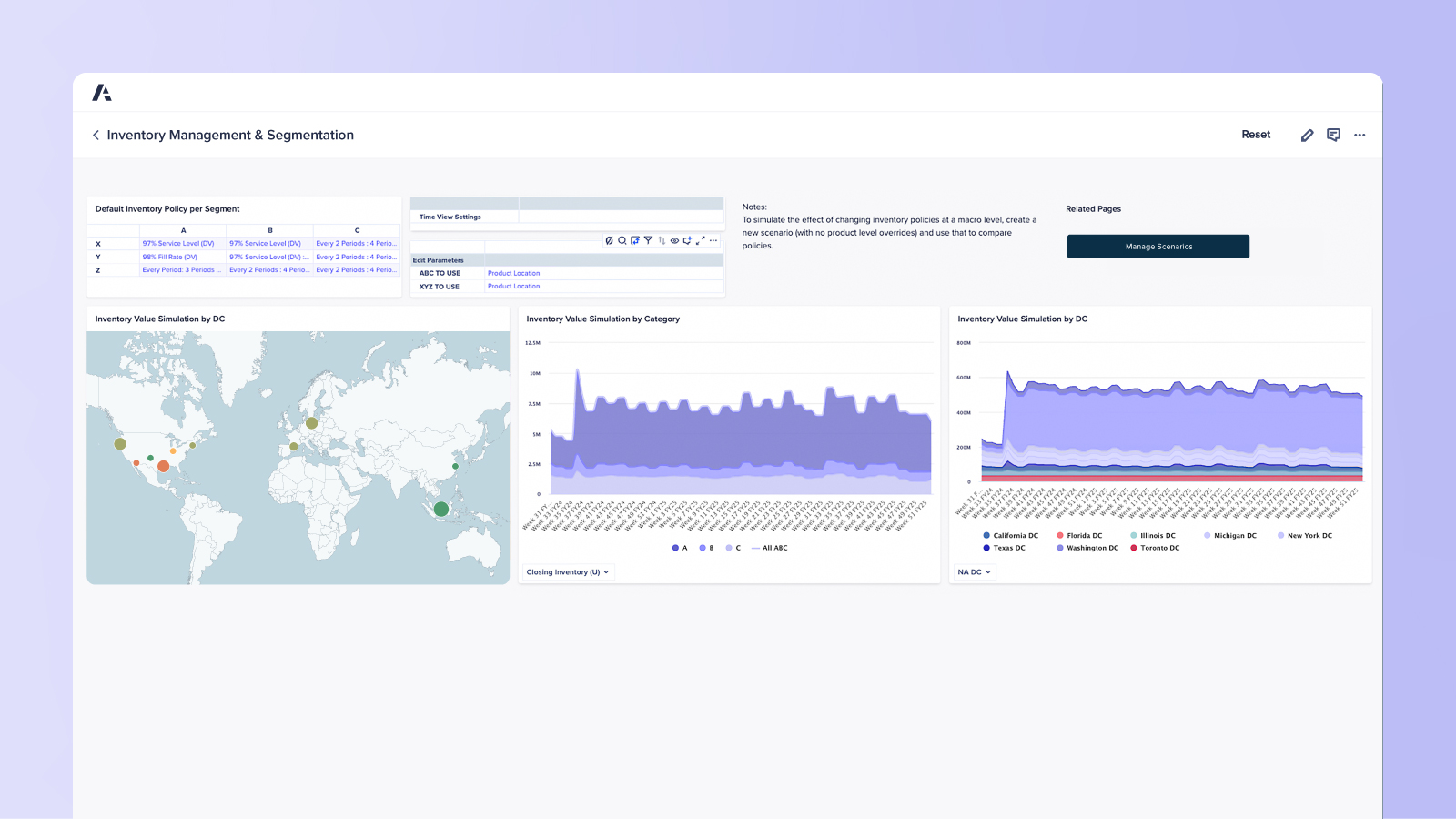

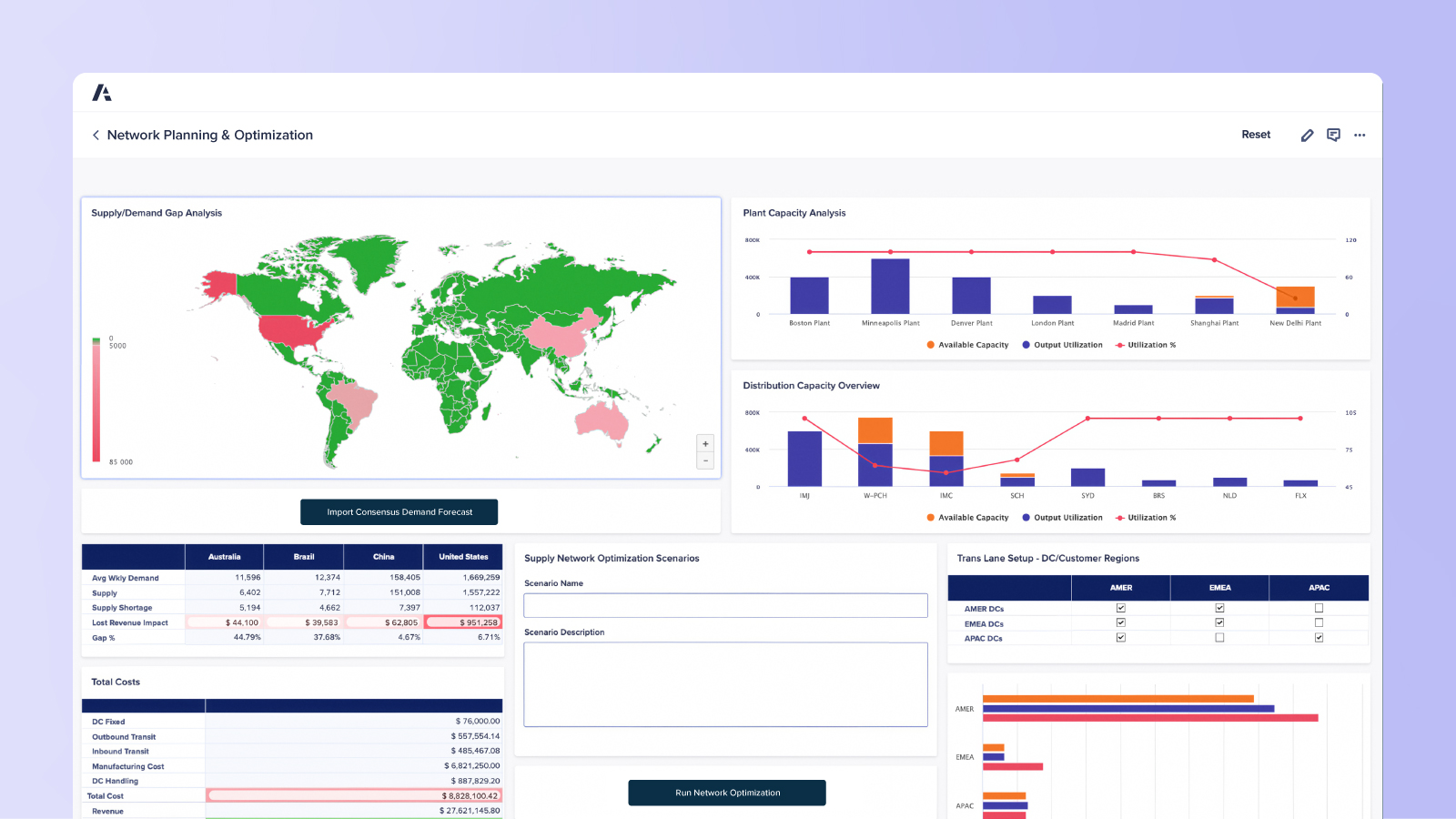

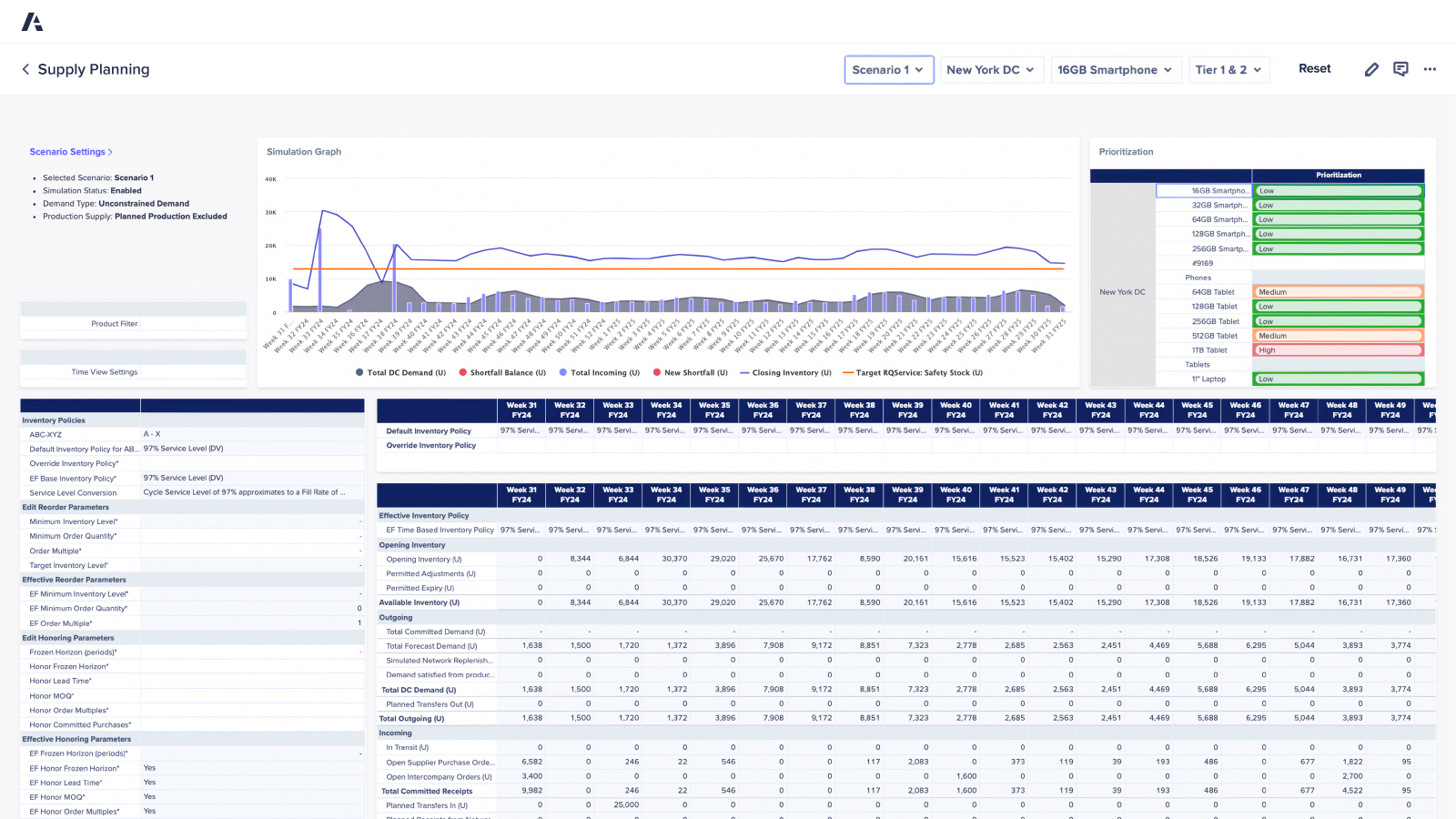

Supply planning

Optimize resources. Drive profitable supply decisions.

AI-infused scenario modeling and analysis solutions for production, capacity and material requirements planning.

Smarter supply planning at any

stage of maturity

From rough-cut capacity planning to fully optimized production planning — transform your supply planning operations.

IDC MarketScape: Worldwide Supply Chain Planning Overall 2024 Vendor Assessment

Anaplan has been recognized as a Leader, highlighting our deep integration across key functional areas and our strategic emphasis on out-of-the-box functionality with embedded best practices.

Optimize decisions with an integrated approach to supply planning

Top supply chain leaders

plan with Anaplan

Discover the platform supply chain leaders trust.

Be the next.

Find out how you can increase the impact supply chain decisions have on the business.