Learn why connected enterprises drive higher shareholder returns

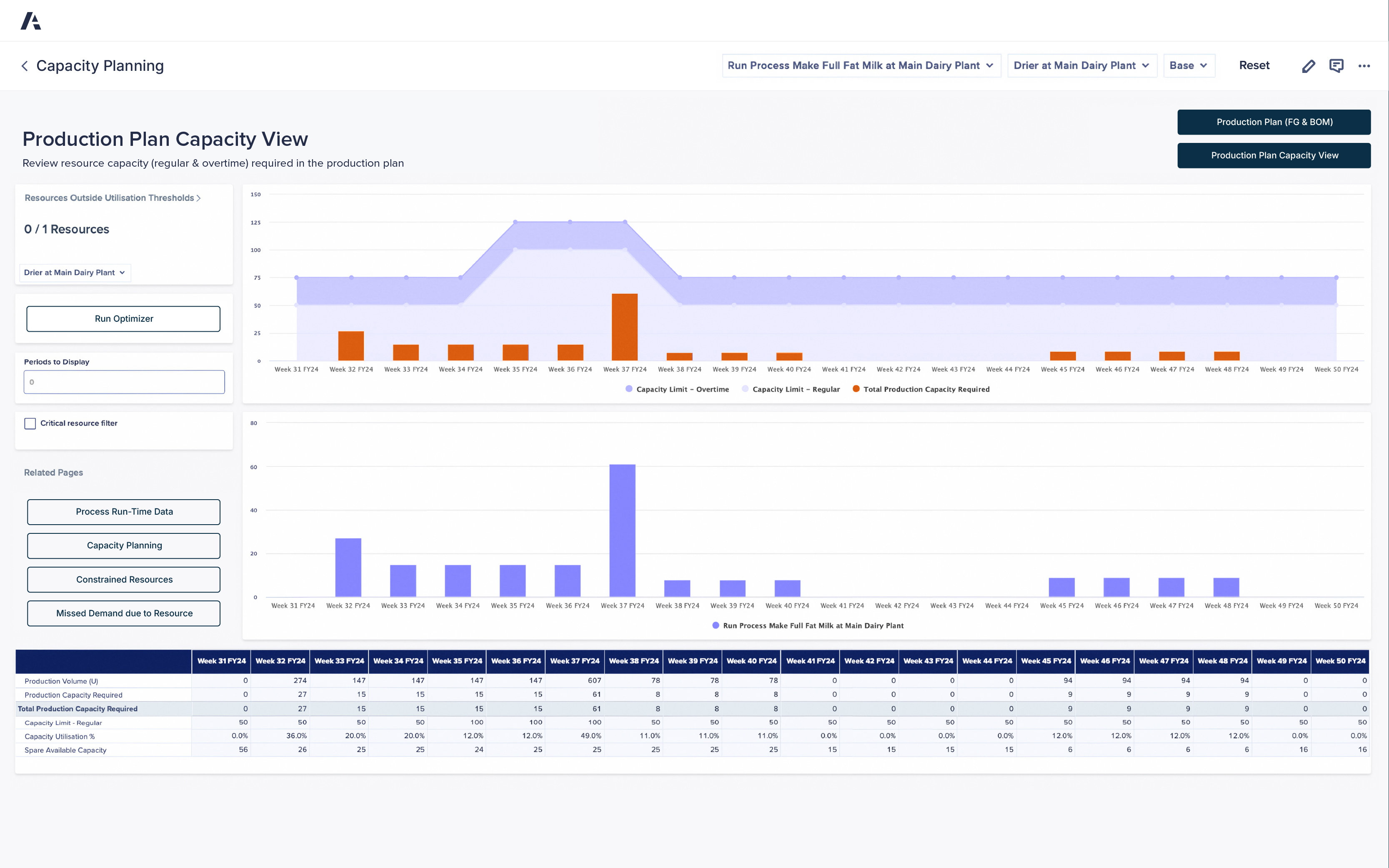

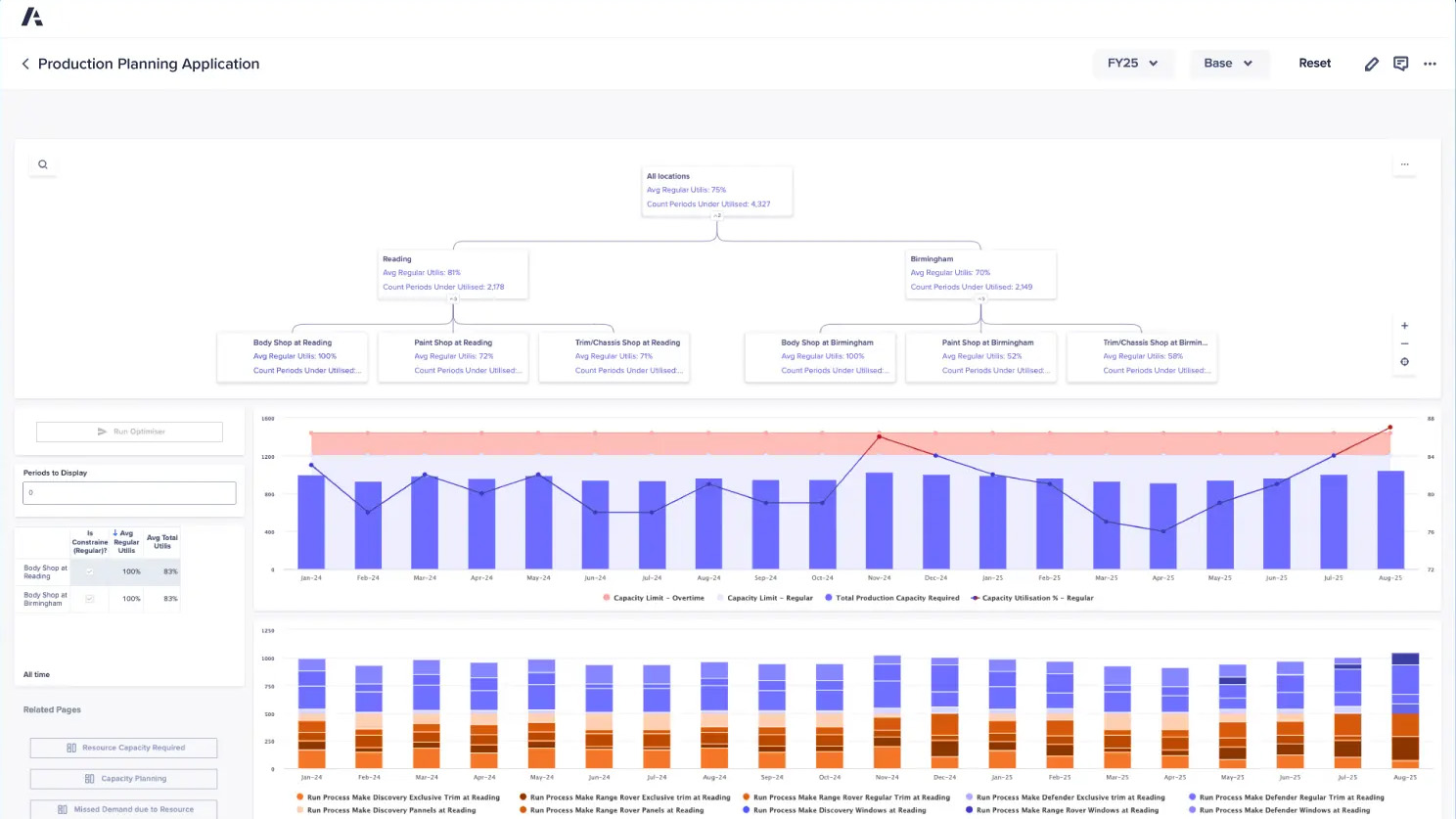

Supply chain capacity planning

AI-driven solutions

for supply chain

capacity planning

Improve service levels, reduce costs, and mitigate risk with intelligent, scenario-based capacity planning.

Balance your demand and capacity with confidence

Anaplan Supply Planning application

Connect across your supply chain with a purpose-built application to optimize production and capacity planning.

Optimize resources at every level with supply chain capacity planning

“The complexity of our business has grown exponentially… Managing this scale requires a new level of planning and coordination across demand, supply, and business strategy. The ability to adapt quickly and efficiently is what drives our success.”

Angela Ying, Vice President of Business Operations, NVIDIA

Discover the platform supply chain leaders trust. Be the next.

Supply chain teams around the world rely on Anaplan to build a modern, connected enterprise. Shouldn’t you?