Anaplan has acquired Syrup Tech

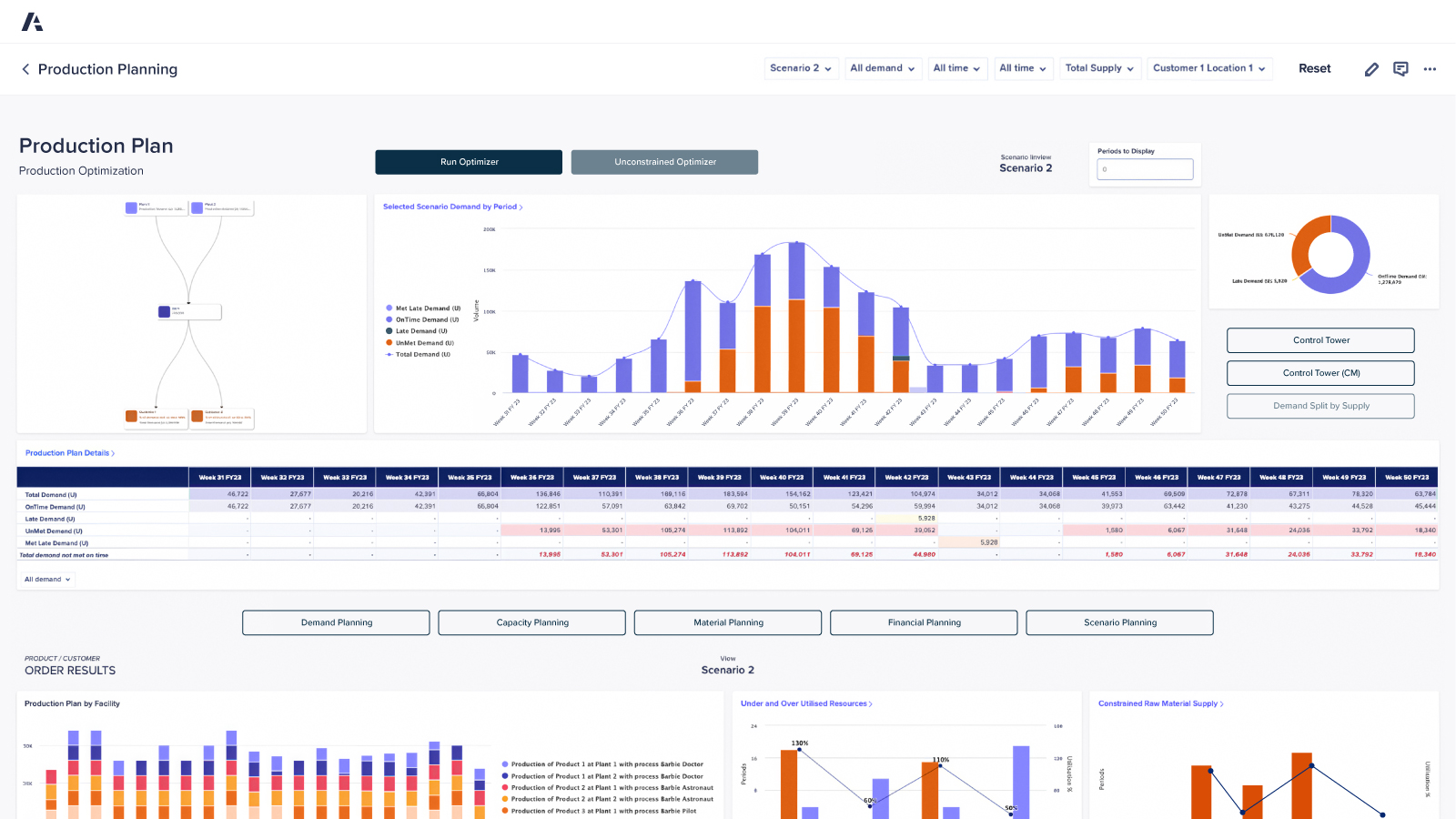

Production planning

Optimize production. Stay ahead of change.

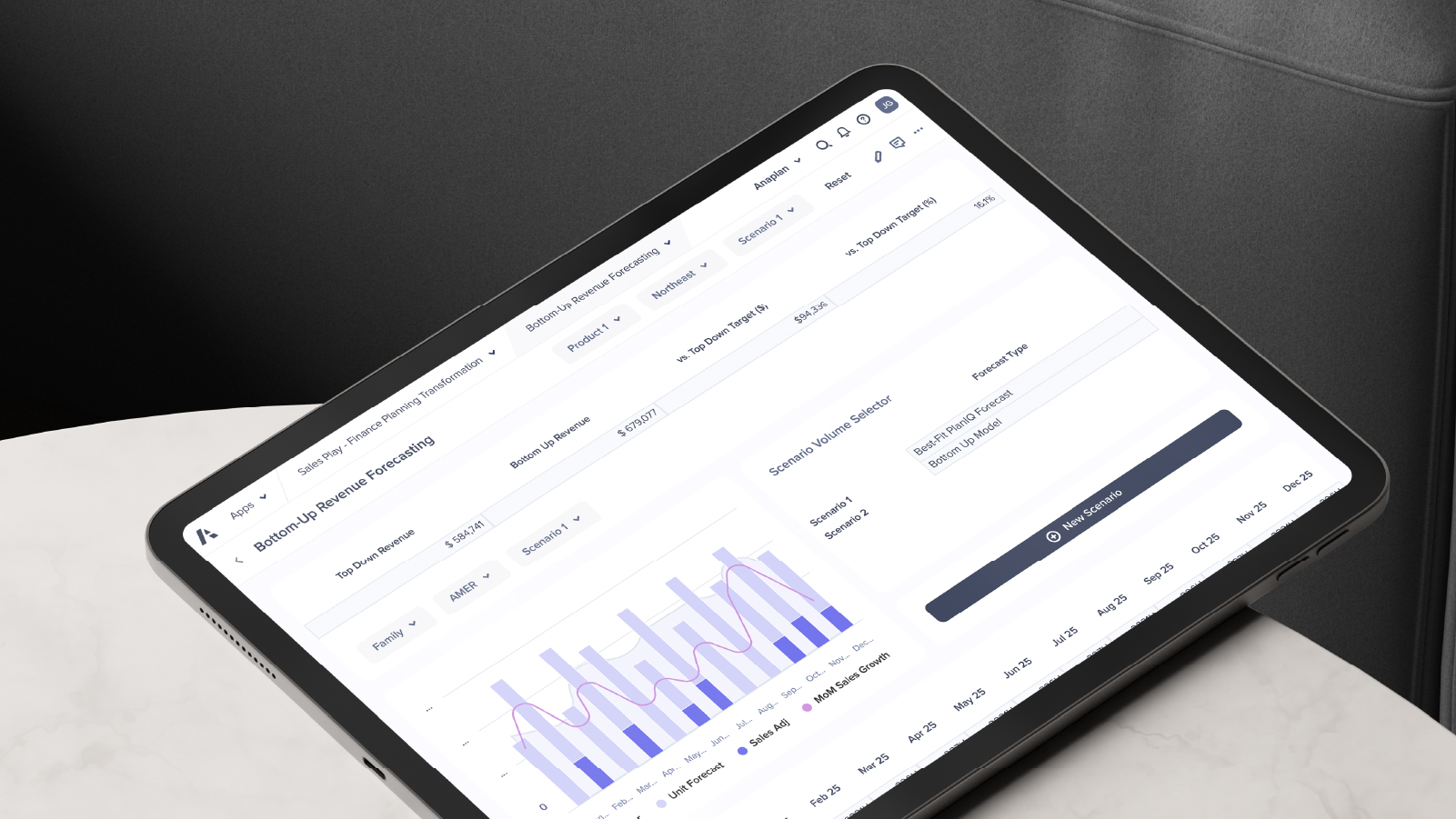

AI-driven scenario modeling and analysis solutions for production, materials, and capacity planning.

Faster, more confident production decisions

Quickly determine how to allocate resources, materials, and production capacity through a multi-dimensional, attribute-based planning process.

IDC MarketScape: Worldwide Supply Chain Planning Overall 2024 Vendor Assessment

Anaplan has been recognized as a Leader, highlighting our deep integration across key functional areas and our strategic emphasis on out-of-the-box functionality with embedded best practices.

Top supply chain leaders

plan with Anaplan

Discover the platform supply chain leaders trust. Be the next.

Find out how you can increase the impact production planning decisions have on the business.